what is solid surface and how to use it?

You may have come across the rising popularity of solid surface, a material that has gained recognition as a design essential in the architectural and interior design fields, particularly in areas that require durability and hygienic surfaces beyond traditional countertop applications. However, what exactly is solid surface?

When comparing solid surface to materials like wood, plastic laminate, metal, or stainless steel commonly used in construction, its composition and performance qualities offer substantial short- and long-term advantages. To introduce why WBstone prioritizes this incredibly versatile material in our product construction, we have provided a brief overview of solid surface below.

What is solid surface?

Back in 1963, solid surface was just an idea brewing in the mind of Don Slocum, a researcher at DuPont™ Chemical Company. His vision was to develop a product that would tick all the boxes: durability, hygiene, and aesthetic appeal, all while maintaining a consistent material and color throughout. While popular materials like granite, marble, and laminate were widely used in construction, they had their limitations. Being naturally porous or relying on porous substrates, they were prone to deterioration over time and could harbor harmful bacteria.

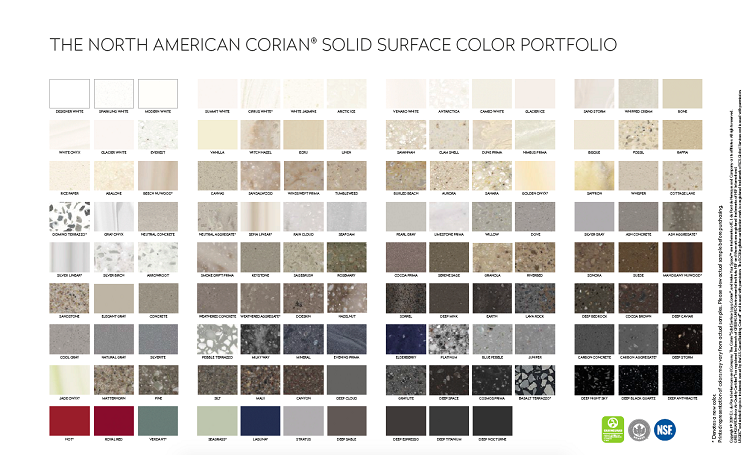

Slocum teamed up with researchers and engineers at DuPont to bring his idea to life, and in 1964, they successfully created the first sheets of solid surface. They named it Corian®. Since then, various companies have jumped on the solid surface bandwagon, each introducing their own brands such as LG HI-MACS®, DuPont™ Corian®, Aristech Avonite Surfaces®, and Lotte Staron®, to name just a few.

How is solid surface made?

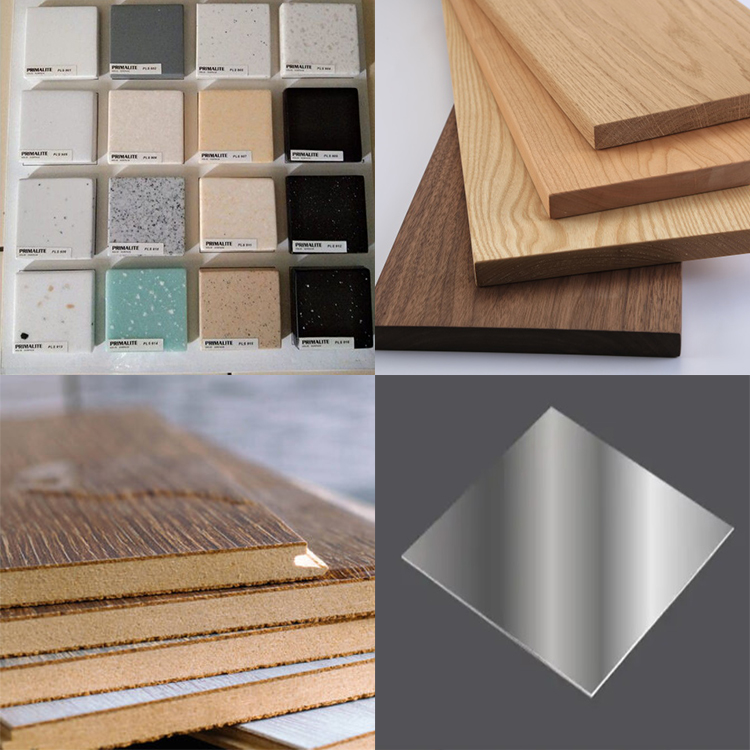

The process of making solid surface is akin to baking a cake. Just like a cake requires dry ingredients, liquids, food dyes, and decorations, solid surface production involves a mix of filler, binder, pigments, and particulates. Let's take a closer look at each of these "ingredients" in the solid surface recipe.

Filler

Think of the filler as the dry ingredients in a cake, such as flour, sugar, or baking soda. In solid surface, Aluminum Trihydrate (ATH) is commonly used as the filler. This natural mineral, resembling stone dust in the form of white powder, adds tensile strength to the final product. This strength allows solid surface products to bear loads without weakening.

Binder

The binder acts as the syrupy liquid that binds all the ingredients together, just like eggs do in cookies. In solid surface, the binder is typically a resin derived from plants. Acrylic resin is commonly used, as it creates a stronger and more moldable solid surface sheet. Polyester resin is another option, producing a slightly more brittle sheet with a glossy finish.

Pigment

Pigments are added to the mix to create color, just like cocoa powder in a chocolate cake or food coloring in icing. The availability of numerous pigments allows for an almost endless array of color options in solid surface. Each manufacturer typically offers a set of standard color choices to streamline production and control costs. However, some colors can be closely matched between different solid surface manufacturers.

Particulates

Particulates are chips of solid surface in various sizes that are reintroduced into the mix to create patterns or designs in the final product. They are akin to vanilla swirls in chocolate brownies or chocolate chips in cookies. Particulates offer almost limitless design possibilities, including mimicking the textures and finishes of natural stone.

The combination of ATH and resin forms the foundation of solid surface, while pigments and particulates are added during the casting process to achieve the desired color and design.

Where do we use solid surface?

Residential Kitchens and Bathrooms

Solid surface countertops, sinks, and backsplashes are popular choices in residential kitchens and bathrooms. They offer a seamless, non-porous surface that is easy to clean, resistant to stains, and provides a hygienic environment.

Commercial and Hospitality Spaces

Solid surface is widely used in commercial settings such as hotels, restaurants, and offices. It is favored for its durability, ability to withstand heavy use, and aesthetic versatility. It is often seen in reception desks, bar tops, restroom vanities, and tabletops.

Healthcare Facilities

In healthcare settings, solid surface materials are used for countertops, work surfaces, and wall cladding due to their non-porous nature, making them resistant to the growth of bacteria and easy to sanitize.

Retail and Commercial Displays

Solid surface is often utilized for retail displays, product showcases, and commercial displays. Its ability to be molded into various shapes and sizes allows for creative and unique designs to showcase products effectively.

Educational Institutions

Solid surface is employed in educational facilities for laboratory countertops, cafeteria countertops, and washroom fixtures. Its durability, resistance to chemicals, and ease of maintenance make it suitable for high-traffic areas.

Outdoor Spaces

Solid surface is increasingly used in outdoor applications such as outdoor kitchens, poolside areas, and public spaces. Its resistance to weathering, UV rays, and moisture makes it a durable choice for outdoor installations.

Furniture and Decorative Items

Solid surface materials are also utilized in the creation of furniture pieces like tables, chairs, and shelves. Additionally, it can be shaped into decorative items such as sculptures, vases, and wall panels.

The main advantages of using a solid surface

Durability: Solid surface is highly durable, eliminating the need for frequent replacements or repairs. This long-lasting nature saves you money in the long run.

Easy Maintenance: Keeping solid surface products clean is a breeze. Its non-porous surface resists stains, making it simple to maintain and keeping your investment in excellent condition.

Repairability: Should scratches or gouges occur, solid surface can be easily repaired. This feature ensures that your surfaces can be restored to their original appearance without the need for costly replacements.

Hygienic: Solid surface materials are inherently hygienic, as they are non-porous and resistant to the growth of bacteria. This quality creates a safer environment for everyone who comes into contact with the product.

Stunning Design: Solid surface offers a range of attractive and sleek design options. Its seamless appearance and versatility allow for stunning aesthetics that enhance the overall look of any space.

Customizability: With solid surface, you have the freedom to bring your vision to life. Its customizable nature allows us to manufacture and build products exactly to your specifications, ensuring that you get the perfect solution tailored to your needs.

- Blog Categories

- Industrial Knowledge

WANBEST

WANBEST

WANBEST

WANBEST